Credit: flickr

After years of trying to get a PhD, publishing papers, networking with professors, and trying to land that one, elusive, permanent job in science, it can be quite easy to forget that you actually do have career options outside of academia. To get a little taste of this, Nico Schliffke, PhD student in geodynamics at Durham University, tries out the industry life for a few weeks!

When coming close to the final stages of a PhD life, many students reconsider whether they want to stay in academia or prefer to step over to industry or other non-academic jobs. This is surely not a simple decision to take, as it could strongly shape your future. In this blog post, I would like to report my industrial placement experience during my PhD and share a few thoughts on the topic.

When coming close to the final stages of a PhD life, many students reconsider whether they want to stay in academia or prefer to step over to industry or other non-academic jobs. This is surely not a simple decision to take, as it could strongly shape your future. In this blog post, I would like to report my industrial placement experience during my PhD and share a few thoughts on the topic.

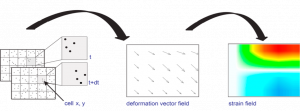

The taste of industry life was an opportunity I had within the frame of my PhD project. Split into two terms, I spent four weeks at a medium-sized company developing optical imaging techniques (both software and equipment) to measure flow fields and deformation. The branch I worked in was “digital image correlation” (DIC) which measures strain on given surfaces purely by comparing successive images on an object (see figure below). This technique is used in both industry (crash tests, quality assessments, etc.) as well as in academia (analogue experiments, wind tunnels, engineering..), and has the substantial advantage of measuring physical properties precisely, without using any materials or affecting dynamical processes. DIC is not directly related to or used in my PhD (I do numerical modelling of subduction zones and continental collision), but surprisingly enough I was able to contribute more than expected – but more on that later.

Basic principle of ‘digital image correlation’. A pattern on a digital image is traced through time on successive images to calculate displacements and strain rates.

Credit: LaVision

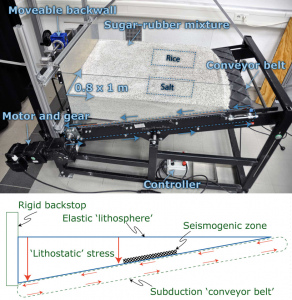

The specific project I worked on was inspired by the analogue tectonics lab at GFZ Potsdam, that uses DIC measuring systems to quantify and measure the deformation of their sandbox experiments. Typical earthquake experiments like the figure below span periods of a few minutes to several days during which individual earthquakes occur in a couple of milliseconds. The experiment is continuously recorded by cameras to both monitor deformation visually and quantify deformation by using the optical imaging technique developed by my host company. To resolve the deformation related to individual earthquakes, high imaging rates are required which in turn produce a vast amount of data (up to 2TB per experiment). However, only a small fraction (max. 5%) of the entire dataset is of interest, as there is hardly any deformation during interseismic periods. The project I was involved in tried to tackle the issue of unnecessarily cluttered hard discs: the recording frequency should be linked to a measurable characteristic within the experiment, e.g. displacement velocities in these specific experiments, and controlled by the DIC software.

Setup of the analogue experiment to model earthquakes in subduction zones (courtesy of Michael Rudolf). Cameras above the experiment measure deformation and strain rates by tracking patterns on the surface created by the contrast of black rubber and white sugar.

My general task during the internship was to develop this idea and the required software. We finally developed a ‘live-extensometer’ to calculate displacements between two given points of an image during recording and link its values to the camera’s recording frequency. Therefore, restricting high imaging rates to large (and fast) displacements of earthquakes should result in reducing the total amount of data acquired for a typical earthquake experiment by 95%. However, we needed an actual experiment to verify this. So, I met up with the team at GFZ to test the developed feature.

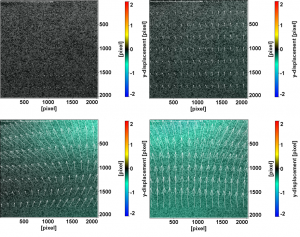

The main experiment the GFZ team had in mind is sketched in the figure above: a conveyor belt modelling a subducting slab continuously creates strain in the ‘orogenic wedge’ which is released by earthquakes leading to surface deformation. Cameras above the experiment monitor the surface while software computes strain rates and displacement (see figure below). The developed feature of changing frequencies during the experiment depending on slip rates was included and worked surprisingly well. Yet freshly programmed software is seldom perfect: minor issues and bugs crept up during the experiments. My final contribution during the internship was to report these problems back to the company to be fixed.

Displacement measured by ‘digital image correlation’ during an earthquake lasting ~5 ms (courtesy of Mathias Rosenau).

My geodynamical background allowed me to contribute to various fields within the company and resulted in various individual tasks throughout the internship: coding experience helped with discussing ideal software implementations and testing the latest implemented software on small (physical) experiments. My knowledge of various deformation mechanisms and geosciences in general, with its numerous subdisciplines and methods, provided a solid base for searching further applications for the developed software within academia, but also in industry. Last but not least, pursuing my own large project (my PhD) strongly facilitated discussing possible future development steps.

The atmosphere at the company in general was very pleasant and similar to what I experienced at the university: relaxed handling, pared with discussion how to improve products or use of new techniques that might be applicable to a problem. To stay competitive, the company needs to further develop their products which requires a large amount of research, developments and innovative ideas. Meetings to discuss further improvements of certain products were thus scheduled on a (nearly) daily basis. On the one hand this adds pressure to get work done as quickly as possible, but working on a project as a team with many numerous areas of expertise is also highly exciting.

This internship help reveal the variability of possible jobs that geodynamicists can have in industry besides the ‘classical’ companies linked to exploration, tunnel engineering or geological surveys. The skill set acquired in a geodynamical PhD (coding, modelling, combining numerics, physics, and geosciences) makes a very flexible and adaptive employee which is attractive to companies who are so specialised, that there is (nearly) no classical education at university level. Jobs at small to medium-sized companies are often harder to find, but it’s just as difficult for the companies to find suitable candidates for their open positions. Hence, it may be worth searching in-depth for a suitable job, if you are considering stepping out of academia and maybe even out of geoscience as well.

If PhD students are hesitant whether to stay in academia or change into industry, I would advise to do such a short internship with a company to get a taste of ‘the other side’. During a PhD, we get to know academic life thoroughly but industry mostly remains alien. Besides giving a good impression of daily life at a company and how you can contribute, an industry internship might also widen your perspective of which areas might be relevant to you, your methodology and your PhD topic. In total, this internship was definitely a valuable experience for me and will help when deciding: academia or industry?

Here are a few links for more information:

Host company

Digital Image Correlation

TecLab at GFZ Potsdam

Previous EGU blog post interviews of former geoscientists