“We can’t manage what we can’t measure”, said Peter Drucker, the founder of business management. Let’s see whether this applies to water management as well – especially agricultural water management. As part of my PhD project, I am wondering to what extent new (or alternative) hydro sensors may contribute to the improvement of the performance of irrigated agriculture.

As the pressure on water resources increases due to climatic and anthropogenic changes, irrigated agriculture has to improve its productivity. We have to maintain acceptable levels of production while limiting our water withdrawals. This objective translates into a quest for performance, which often means improving management.

But can better measurements help us to do so? And if so: What should we measure? How? And for whom?

Irrigated agriculture: struggling with a lack of data

These are some questions that we asked within the framework of the HubIS research project, of which my thesis is a part. This PRIMA project covers several irrigated territories in the Mediterranean area which face performance issues and whose sustainability is threatened. The project combines stakeholder surveys and experimental work and highlights the main needs and constraints of Water User Associations (WUA) with regard to irrigation practices.

For instance, in Provence (South of France), water flows freely through a network of irrigation canals and WUA officers need to ensure efficient and equitable distribution without having access to continuous measurements. At farm scale, surface irrigation is complex: Water flows temporarily over fields, and it is difficult to avoid excessive losses through run-off and deep percolation without spending all your time keeping an eye on the water front.

Another situation can be found in Cap Bon, an agricultural region in northern Tunisia. Here, drip irrigation of market crops on draining sandy soils is the challenge. Farmers complain that they have invested heavily in localised irrigation equipment, but are failing to reduce irrigation costs and irrigation volumes. The reason appears to be that irrigation schedule management is complicated by the lack of training and information, as well as by the variability of the water flows delivered by the collectively managed network.

In short, water users’ comments in both territories insist that the lack of information stops them from optimising their practices. They can’t manage what they can’t measure.

Developing innovative low-tech for water management

Better access to information could therefore facilitate water management at different scales, and improve the performance of irrigated agriculture. Several such tools already exist, and many hydrologists are familiar with them: agro-hydraulic models, commercial sensors such as pressure and soil moisture probes, or remote sensing products. However, in practice, these tools are not widely used in agriculture, especially not by small-scale farmers or in the global South.

Use of the Pilowtech by a pilot farmer, Tunisia. © P.Vandôme

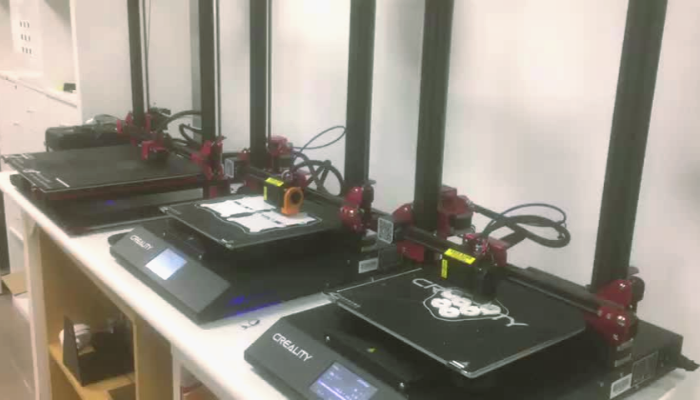

For this reason, my work focuses on the design of new hydro sensor tools for decision support that are accessible and adapted to the agricultural sector and stakeholder-specific requirements. To design these tools, my group implemented a participatory method of innovation co-design, through the creation of Fabrication Laboratories (Fab Labs). These are open spaces for water users which provide the necessary material for the (re-)design, replication, and maintenance of hydro sensors.

Fab Lab at Chraf irrigation scheme, Tunisia. © S.Moinard

The first systems developed in France and Tunisia allow the measurement of different variables for local water management requirements.

For instance, our “WatAr”(Water Arrival) sensor allows the detection of surface water advancement using a simple floating system. The information about water detection is transmitted through a local radio network and then sent on to the end user in the form of an online messaging alert. Properly located on the plot, this low-tech sensor helps farmers optimise gate management.

Pilowtech soil moisture sensor, Tunisia. © P.Vandôme

Another example is the “Pilowtech” sensor, developed for irrigation scheduling in Tunisia. This capacitance-based soil moisture sensor comes with a simple calibration method that can be carried out in the field, without the need for laboratory equipment or advanced technical skills. Designed to be widely accessible, this low-cost sensor is 50 to 100 times less expensive than commercial soil moisture sensors. Cost minimisation is made possible by the use of cheap or 3D printed hardware components and open-source software and interfacing.

3D printers producing the casing for the low-tech hydro sensors. © P.Vandôme

Despite adaptations specific to each territory, our innovations have some common features. They are low-tech, meaning they are easy to design, maintain and reproduce. They are low-cost, meaning they can be adopted by the majority of farming systems, and may be multiplied to increase measurement points. And they are wireless and low-power, which means that they are autonomous and provide remote and continuous real-time information.

Each innovation is tested in the field by “pilot farmers”, to check and improve their functioning with user’s feedbacks. Then, we can seek to answer our next question: Now that we can widely measure, can we finally manage?

Edited by Christina Anna Orieschnig