We chatted with a marine biologist about her exciting journey from academia to becoming an entrepreneur. Discover how her algae farm start-up came to life, learn about the concept, achievements, and challenges she faced, future plans, and finally her advice as well as her take on the importance of bridging the two worlds of academia and industry.

Dr. Mar Fernández-Méndez is a marine biologist dedicated to mitigating climate change by sequestering carbon in the ocean through nature-based solutions. She leads the Helmholtz Young Investigator Group at the Alfred Wegener Institute Helmholtz Centre for Polar and Marine Research and is the CEO of the start-up MacroCarbon.

🌊Tell us about your journey from being a marine biologist in academia to becoming an entrepreneur! What inspired you to focus on algae for climate protection?

I started studying marine microbiology in 2009 because I believed that microbes could solve climate problems. During my PhD on Arctic phytoplankton, I realized the importance of phytoplankton, taking up carbon and sequestering it, though measuring carbon sequestration proved complex.

Traveling to the Arctic regularly, I witnessed its rapid degradation, showing that climate change is happening now. These realizations led me to focus on macroalgae, which are more efficient at carbon sequestration and easier to monitor, allowing for scalable solutions to make a real impact on climate change and protect the ocean we rely on.

🌊 How did the startup begin? And how does your seaweed farming model work?

In 2020, I shifted my focus to macroalgae, specifically Sargassum, and joined Francisca Elmer to create the Sargassum Podcast. We interviewed scientists, entrepreneurs, and locals dealing with this brown algae, which has heavily accumulated on the Caribbean coast since 2011. Inspired by an interview, a serial entrepreneur founded Seafields to cultivate Sargassum for carbon sequestration, and I joined as a co-founder and scientific advisor, gaining my first insights into startup creation. We conducted our first field trials in the Caribbean to explore its potential.

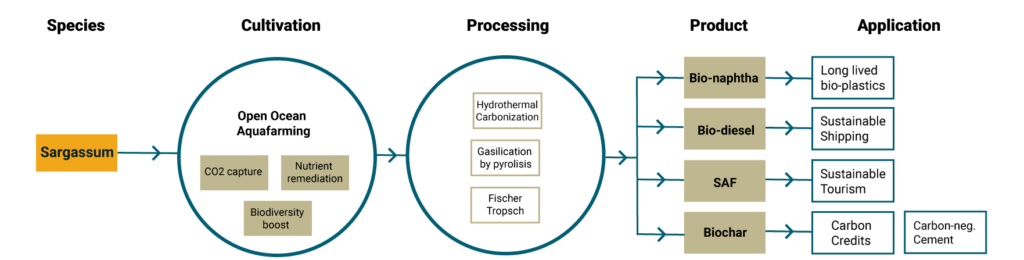

In 2022, I won a grant through the Alfred Wegener Institute, where I was working as a Helmholtz Young Investigator Group Leader, at the Carbon-To-Value Challenge from the German innovation agency, SPRIND, with Jason Cole, head of innovation at CarbonWave. We described a pathway to cultivate Sargassum in the ocean, but instead of sinking it into the deep ocean for carbon sequestration as Seafields had envisioned, using Sargassum biomass to create products that store carbon. Initially focusing on producing bioethanol through fermentation, we shifted to gasification by pyrolisis and Fischer Tropsch technology to produce sustainable hydrocarbons such as sustainable aviation fuels, bionaphtha or marine biodiesel. This process also produces biochar and carbon black as a side product, which permanently sequester carbon.

In 2023, Jason and I founded MacroCarbon, a spin-off from the Alfred Wegener Institute and Carbon Wave, continuing our work in the Canary Islands. My experience with Seafields gave me the confidence to take on this challenge.

MacroCarbon‘s model (credit: MacroCarbon)

🌊 What progress have you made so far? What’s the difference to traditional seaweed farming? Why did you choose Sargassum and Ulva?

Seaweeds are very efficient at carbon sequestration due to their high carbon-to-nutrient ratio, needing fewer nutrients than phytoplankton to sequester the same amount of carbon. Traditional seaweed farming is coastal, using buoys and lines, but pelagic Sargassum floats and grows in the open ocean, allowing larger-scale farming. It reproduces through fragmentation, eliminating the need for hatcheries. Contained in a floating barrier, its rapid reproduction offers a low-cost biomass option for biofuels. So far, we conducted a successful 1-month trial in the Caribbean to explore Sargassum’s potential. In Gran Canaria, a trial was hindered by a lack of Sargassum. We are now waiting for more Sargassum in March to monitor it for a year.

Ulva is chosen for cultivation as a native green algae species in the Canary Islands, valued for its sulfated polysaccharides. It’s grown in ponds or raceways using wastewater from fish hatcheries on Gran Canaria. Although this approach is less scalable than Sargassum, it offers high value.

The trials for Ulva and Sargassum are currently still lab-scale, producing small amounts for testing. Operations in the Canary Islands confirmed growth rates and low nutrient needs, aided by iron from Sahara dust, by successfully maintaining Sargassum in a land-based raceway for five months. However, no one has proven yet that they can keep a culture offshore in an aquafarm for a year. The company is raising funds to scale up production. Unlike academia, which often stops at lab scale, the company aims to implement solutions at a larger scale.

🌊 What are the other challenges in cultivating Sargassum on a large scale in the open sea?

One of the main challenges in cultivating Sargassum on a large scale in the open sea is obtaining permits. Permitting is complex because authorities are unfamiliar with seaweed cultivation, often treating it like fish aquafarming. Funding is another challenge, as it requires delivering results by specific dates, but delays in permits can hinder that. Additionally, biological and technical issues come up, such as timing operations with the availability of Sargassum biomass. We also face the challenge of public awareness; the average person in the Canary Islands isn’t aware of our work, and we need to inform them to create jobs and maintain the local economy.

🌊 What are next steps? What future developments or innovations is MacroCarbon exploring?

The next step is to scale up our operation from a 2,000 to a 40,000 m² aquafarm by 2025, pending funding. We’re innovating by designing novel infrastructure and attempting to domesticate benthic species like Aargassum and Ulva to grow floating. This involves creating 3D-printed floating structures. In processing, we’re, for example, working on a new way to process wet seaweed without drying it first, and other steps to make production more efficient

In terms of the carbon impact that we want to create with this, our life cycle assessment shows that, we can sequester 12,000 tons of CO₂ per square kilometer per year in products. This is without taking into account the natural sinking of Sargassum, something we are also researching at AWI. 88% of carbon sequestered ends in the product. The remaining 12% emissions mainly come from infrastructure creation and not from direct emissions.

🌊 How have your experiences influenced your approach to this venture? What advice do you have for aspiring ocean science entrepreneurs?

Being part of Seafields showed me that starting a venture is doable and not overly complicated. Surrounding yourself with inspiring and supportive people is crucial. If you can learn mathematical modeling for carbon uptake, you can also learn business skills like creating a business plan or doing a cash flow analysis. Scientists already have many of these skills from academia, like writing proposals, managing budgets, pitching, and negotiating.

My advice to aspiring entrepreneurs is to recognize these skills and dare to take the risk. It’s fun and essential for implementing solutions to mitigate the climate crisis. Staying at the basic level of studying won’t change anything. We’ve given enough warnings to political spheres; now it’s about convincing investors and the public that solutions must be economically viable.

🌊 As someone working both in academia and industry, what is your take-home message?

Collaboration between academia and industry is crucial, especially in fields like earth system research, where it’s less common compared to other disciplines such as pharma or engineering. We need to foster closer ties and be open-minded about these partnerships. Individuals with dual careers in academia and industry are valuable as they bridge these worlds. This collaboration is essential for addressing and solving the climate crisis, as scientists who understand carbon and nutrient cycles can help develop, monitor, and verify solutions.

Interviewed and edited by Jacqueline Behncke