Producing deep geothermal energy involves using a well, which can be several kilometres deep, to extract hot water in the aim of using its heat to generate electricity or for industrial applications.

The well is drilled into what’s called a geothermal reservoir; rock containing empty space, or porosity, which allows the passage or storage of fluids. Sometimes hot water is already sufficiently present within the geothermal reservoir, but often cooler water is pumped into the ground via an injection well in the aim of collecting it once it has been heated. The combined use of an injection and a production well is called a doublet and is a common method of exploiting geothermal energy. During the production or it is important to understand what is happening to this water as it is being injected, how much we can expect to get out at the other end and how hot it will be! This involves modelling the movement of the water, the transfer of heat and the mechanical stress and deformation of the rock, all of which are interconnected by coupled, highly non-linear equations.

Antoine Jacquey, of German Research Centre for Geosciences, Potsdam is a PhD student working on methods of reservoir engineering. In his 2016 paper, “Thermo-poroelastic numerical modelling for enhanced geothermal system performance: Case study of the Groß Schönebeck reservoir” demonstrating an improved version of this method, which takes into account the change in porosity as the rock deforms, Antoine Jacquey and his colleagues applied these new techniques to the Groß Schönebeck geothermal facility.

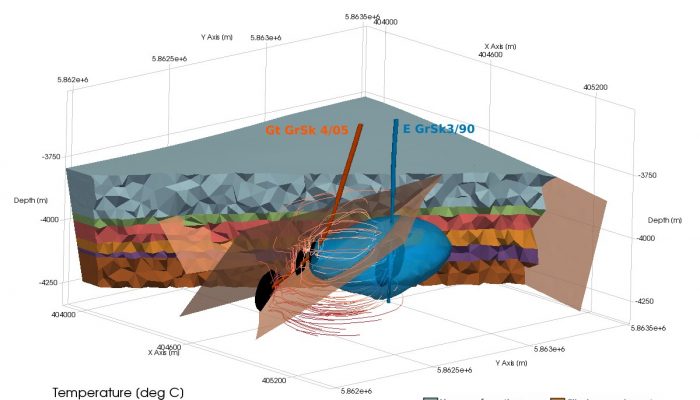

The Groß Schönebeck geothermal reservoir is located just north of Berlin, Germany, and is home to an injection/production well doublet. These wells are used as an in situ laboratory for investigating deep sedimentary structures and fluids under natural conditions. The reservoir, at 4-4.1 km depth, is made of up Elbe base sandstone which has a porosity of up to 10 %. Antoine and his co-authors apply the thermo-mechanical modelling techniques to simulate 100 years of geothermal production at Groß Schönebeck, providing insights on the longevity and productivity for similar geothermal sites. The latter are dependent on temperature drops in both the reservoir and the extracted geothermal fluids which occur as a cold water front moves outwards from the injection well (see Figure above). They find that the injection of cold water enhances the porosity and permeability (the ability of the rock to transmit fluids) which in turn increases the amount of cold water propagating through the reservoir, decreasing the estimated life time of the system from 59 to 50 years. Their study highlights the importance of correctly taking into account the coupling between the different thermo-hydro-mechanical processes.

Antoine Jacquey is currently a PhD student at the German Research Centre for Geociences, Potsdam in section Basin Modelling. His research interests include numerical modelling of coupled thermo-hydro-mechanical processes, deformation of fractured systems and localized and diffused deformation in porous reservoir rocks.